The defense sector is a private and public enterprise employing cutting-edge technology to provide the army, navy, and air force with the next generation of fighting capabilities. Additive manufacturing, often known as 3D printing, is one of the technologies that helps firms in the defense sector better the research, production, manufacturing, and administration of various military equipment and structures.

As a result, the market for 3D printing in the military has been steadily rising throughout the globe. Many experts and writers believe 3D printing is the future of manufacturing weapons and other military items. Defense companies, like other enterprises, employ 3D printing using plastic and metal to join Industry 4.0.

Aside from eliminating subtractive techniques for manufacturing, industrial-grade 3D printers enable the production of tools and parts on demand in remote locations. Furthermore, 3D printing aids military development and research by making testing ideas easier and creating quick prototypes. We can evaluate how much technology will affect things by examining how 3D printing is utilized in the military industry.

Speeding up idea testing and prototyping

One business that has adopted 3D printing to accelerate research and development is defense. Defense businesses continue experimenting with various 3D printers and materials to test concepts and create rapid prototypes. Engineers can create functional concept models and prototypes with fewer tools. Additionally, producing multiple prototype versions swiftly and frequently reduces the time and money required for confirmation testing.

Remotely Manufacturing Replacement Parts

Countries often conduct military operations in remote and difficult-to-access locations. Engineers have difficulty repairing and maintaining automobiles and aircraft when the weather is poor.

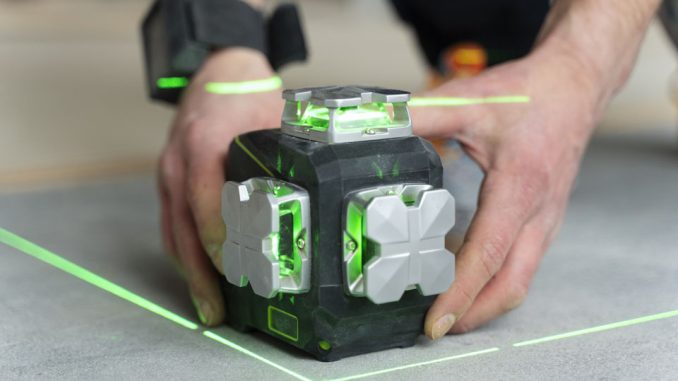

Engineers may use 3D printers to create accurate and reliable materials on demand. In addition, they duplicate the additional item or installation tool using the initial CAD model and typical supplies. Several organizations provide 3D printing services and spare ship components to various locations for military clientele.

Making New Tools

When it comes to vehicle maintenance, military personnel often need new equipment. They must wait a few days for the tools to arrive from the headquarters. However, experts in the United States Navy use 3D printers to create jigs that make removing steering wheels from metal easier. The concept enabled them to reduce wait times and repair automobiles more quickly. The military often uses 3D printers to make it simpler to create items precisely where they are required.

Printing weapons and assembling components

Defense organizations have been printing items using 3D printers rather than building them since 2013. They can use 3D printing to create complex components for defensive equipment. Engineers may also use 3D printers to assist in the production of limited numbers of end components.

Simultaneously, 3D printing allows them to enhance the performance of guns and planes by rendering the end parts lighter. Most military organizations invest money in R&D to find out how to make 3D-print weaponry like rockets or grenade launchers.

Healing Battlefield Injuries

Following a war, more troops are always injured than die. In addition to improving the effectiveness of personal armor, military organizations must consider how to manage wounded on the battlefield. Bioprinting is a 3D printing that allows the military to create precise and rapid biological components.

The military may employ bioprinting techniques to create limbs and devices for individual patients in various locations. Furthermore, military doctors may use 3D printers to improve surgical outcomes by creating instruments and models tailored to each patient.

Building military infrastructure

Governments often establish military infrastructure in remote locations or overseas to expedite military evacuations. Using standard manufacturing methods, they can’t create military installations like airfields in a short period. Industrial 3D printers make it simpler for nations to establish military installations in remote and difficult-to-reach areas without investing additional time and money. Companies can construct movable airfields in a matter of days by 3D printing critical components such as runway matting.

Resolving Material and Design Issues

Engineers must deal with numerous material and design issues when utilizing subtractive manufacturing techniques to create personal armor. They employ 3D printing to overcome typical material and design issues. 3D printers make it simpler to create personal armor with difficult forms, such as bottle caps. Simultaneously, experts can test new materials that safeguard soldiers by improving their ability to absorb shocks in various settings.

Modifying the Military’s Supply Chain

Defense enterprises, like other businesses, invest much in strengthening their supply chain management. They must maintain a network of military enterprises to guarantee that weapons, spare parts, and construction materials are always accessible.

However, 3D printing enables defense organizations to establish digital supply lines. Engineers may create new pieces and structural sections from CAD models using 3D printers. As a result, military agencies no longer have to pay for storage or maintain a network of defense enterprises.

Decreasing the amount of time and funds spent on logistics

Defense organizations struggle to produce spare parts and structural components at remote locations due to a lack of qualified personnel. However, many companies and startups have established themselves by providing 3D printing services to the defense industry.

Military organizations may have parts or components printed near where they will be utilized by partnering with a reliable 3D printing service provider. Local 3D printing businesses help military organizations save time and money on logistics.

Conclusion

The constant growth of the worldwide sector of military 3D printing demonstrates how additive manufacturing has altered the defense industry. Defense firms have increased their investments in additive manufacturing and developed new applications. As a result, the military industry will soon employ 3D printing in various novel and fascinating ways.

However, when examining how 3D printing may be utilized in the defense sector, key issues such as skill gaps, control of quality, and digital security must be addressed. The US Department of Defense has already developed a plastic manufacturing strategy to address these issues. Most countries will reveal identical strategies for 3D printing to transform their defense industries.

Leave a Reply